What’s New in Valor NPI 2305

- Enlight Technology

- Jul 11, 2023

- 3 min read

By Maya Shani

Introduction:

In a response to growing DFM requests from our customers, the latest release of Valor NPI, 2305, our biggest mission was to improve our analysis on positive polarity copper layers. In addition to this, we have also extended our coverage of conveyor related issues with board and rail corners, cleaned up analysis result viewing, provided an ability to graphically view the component VPL side definition and re-organized MRA menus and icons.

Take a peek on a couple of the most exciting improvements introduced in this release.

Validate thermal connection in SMD and drilled pads.

When reviewing thermal pads, the desire is to get adequate copper connection to ensure solid electrical performance, while maintaining sufficient isolation from the plane to prevent heat dissipation and poor soldering.

Valor NPI 2305 covers the above need for both SMD and drilled pads with a set of thermal connection constraints in ADM, some with analysis capabilities improved significantly from previous releases, while others brand new. Simply filter the ADM Constraint list using the term “thermal” and you will get the full list.

To uncover cases where the thermal connection is insufficient run the following constraints:

Thermal spoke connection (Percentage)-positive layers

Drilled Thermal Spoke Count -positive layers

Drilled Thermal Spoke Width – positive and negative layers

Thermal Connectivity Reduction – negative layers

SMD Pad Insufficient Surface/Thermal Connection – Percentage Perimeter – positive layers

SMD Thermal Spoke Count – positive layers

SMD Thermal Spoke Width – positive layers

To uncover the opposite use case and report thermals that do not maintain sufficient isolation from the plane make use of the following constraints:

Large / Small Pin Thermal Connection – positive and negative layers.

No Interceding Thermal – positive and negative layers

Electrical pin missing thermal on plane – positive and negative layers

SMD Pad Excessive Surface/Thermal Connection – Percentage Perimeter – positive layers

SMD Pad Excessive Surface/Thermal Connection – Percentage area -positive layers

Analyze with the ADM design issues regardless of copper layer type or polarity.

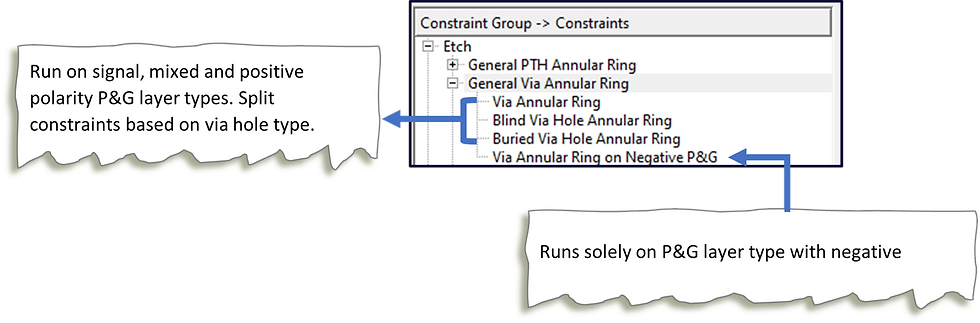

Valor NPI 2305 removes many limitations that existed in the past on getting required analysis results regardless of the copper layer type (power & ground, mixed or signal) and position (inner, outer) and significantly extends the support for positive layer polarity.

This includes:

The ability to setup different annular ring requirements for blind and buried via holes also on power & ground layers.

Analysis support for positive polarity layers in constraints such as: Disconnected Plane, Drills Shorted by Plane and PTH and Via registration.

Support for signal layer type in constraints such as: Drill isolated from Plane.

Support for power&ground layer type in constraints such as: Undrilled Area and Holes Missing Copper.

Reorganization of the Drill to Copper Spacing constraints to enable better refinement of rule management based on hole type and copper feature type.

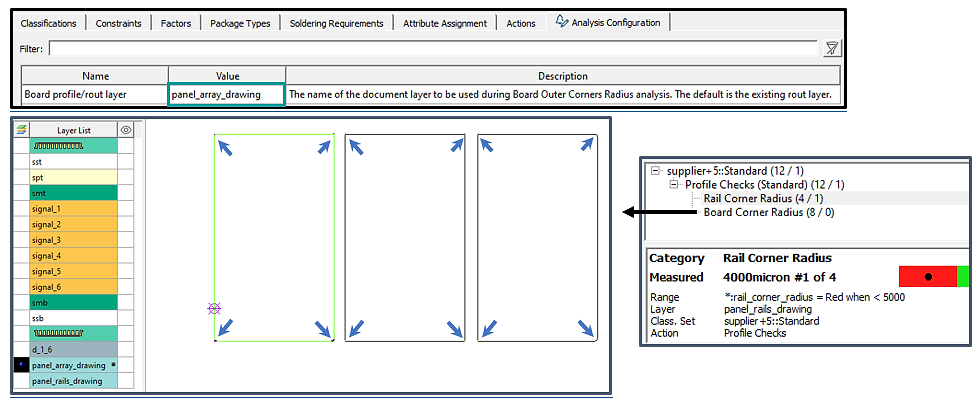

Detect sharp corners of the board and rails.

To avoid blockage on the conveyor or damage during packaging, the board and the rails corners needs to be round enough. Valor NPI 2305 introduces two new constraints that can report corners which are too sharp and therefore could present a risk during the manufacturing process.

Clean up result display with the removal of redundant classification rows.

In previous releases, the review of analysis result was a bit cluttered in cases where violations were split to multiple rows based on a specific classification. In this release redundant category rows of analysis results are unified into one row when all applicable constraint values are identical. The improvement is also applicable to legacy checklist.

Affected Classifiers/Factors are:

Package Type (excluding package type to package type constraints).

Package Side (excluding package type to package type constraints).

Package to Package Orientation.

Pin Type.

Teardrop Features.

Drill Size.

Via Type.

Via Types.

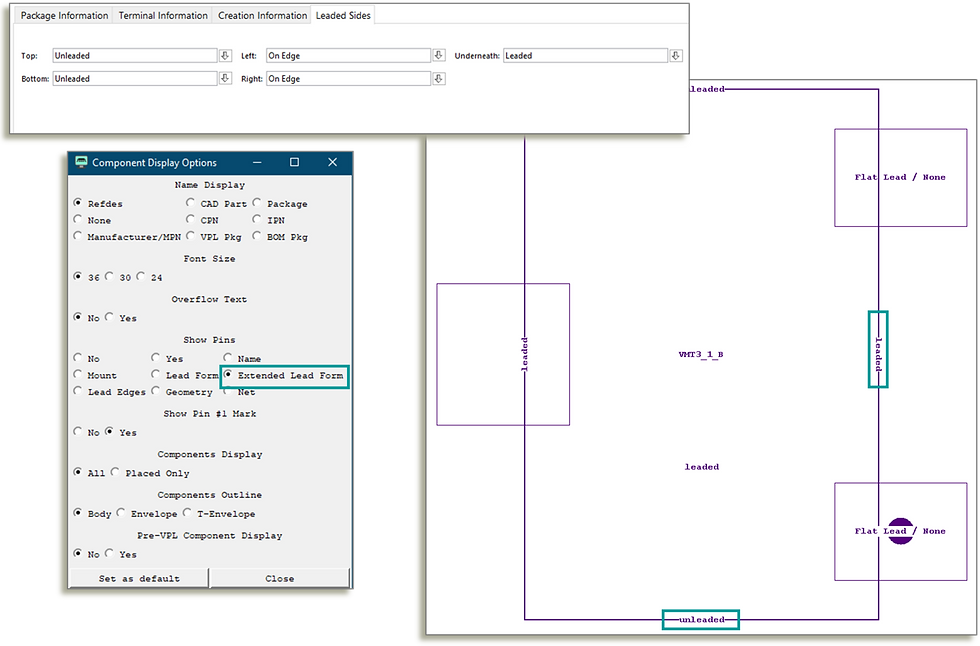

VPL package side definition

In many of the assembly analysis constraints, component side (leaded/unleaded) can promote difference spacing requirements. Valor NPI 2305 enables the user to graphically view the component side as received from the VPL package to enrich the user experience while reviewing analysis results.

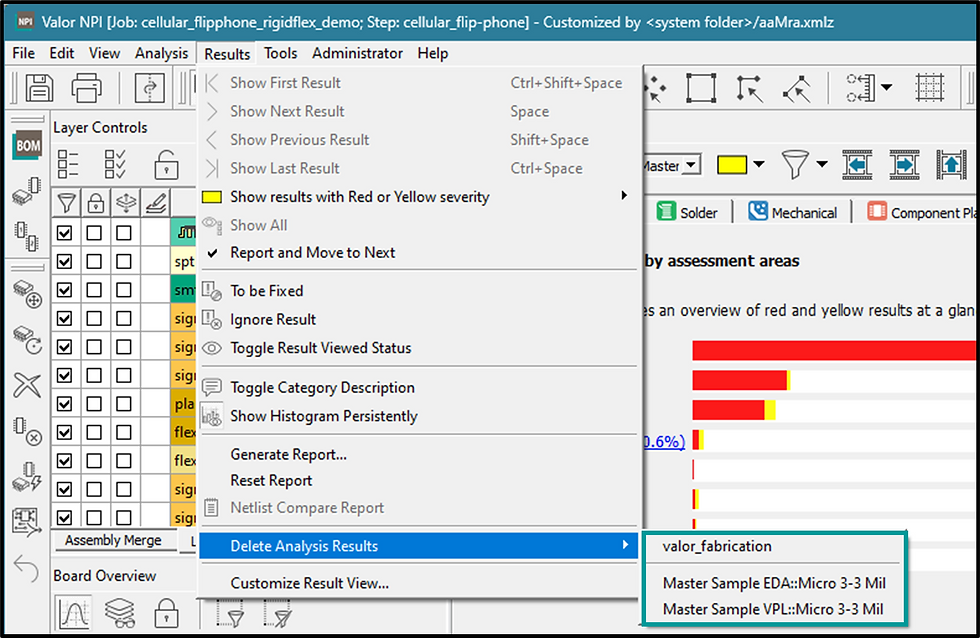

Siemens tools shared user experience in the MRA

Valor NPI 2305 goes a step further in implementing the Siemens tools shared experience with a new look and feel of icons and menu bar. The main toolbar is split into sub toolbars allowing the user better flexibility in arranging the screen. Each toolbar and widget window can be hidden or displayed as preferred or repositined in the MRA workspace.

Deletion of Classification Set results prior to the export of ODB++ is now available through a new MRA menu item.

Summary:

The above topics provides only a glimpse of what you can find in version 2305.

Don’t forget to visit our Valor NPI 2305 page in Support Center and catch up on everything that is new and exciting with the release What’s new and the release highlights documents.

恩萊特科技股份有限公司

Enlight Technology Co., Ltd.

www.enlight-tec.com

電話:03-602-7403

傳真:03-621-0304

sales@enlight-tec.com

Comments